Multi Agent Reinforcement Learning for Supply Chain Optimisation

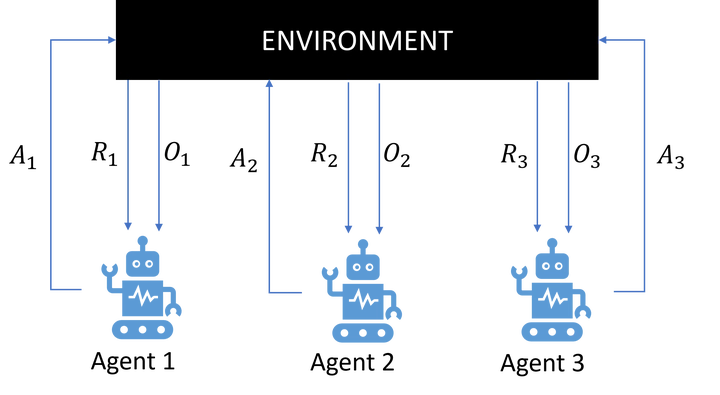

Multi-Agent Reinforcement Learning (MARL) has emerged as a powerful approach to tackle complex decision-making problems involving multiple interacting agents. In the context of supply chain optimization, MARL enables agents to learn and adapt their strategies in a decentralised manner, leading to more efficient and resilient supply chain operations. Unlike traditional centralized optimization methods, MARL allows for the consideration of local objectives and constraints of individual agents, leading to more realistic and effective solutions in dynamic and uncertain environments. In the chemical sector, supply chain optimisation is important due to the inherent complexities and risks associated with handling and transporting hazardous materials. MARL can be particularly beneficial in this context by enabling agents, such as suppliers, manufacturers, and distributors, to coordinate and optimize their operations collaboratively. This can lead to improved inventory management, reduced costs, and enhanced safety and compliance measures, ultimately contributing to more sustainable and competitive chemical supply chains. Thus, the application of MARL in supply chain optimisation holds significant promise for driving innovation and efficiency in the chemical industry.